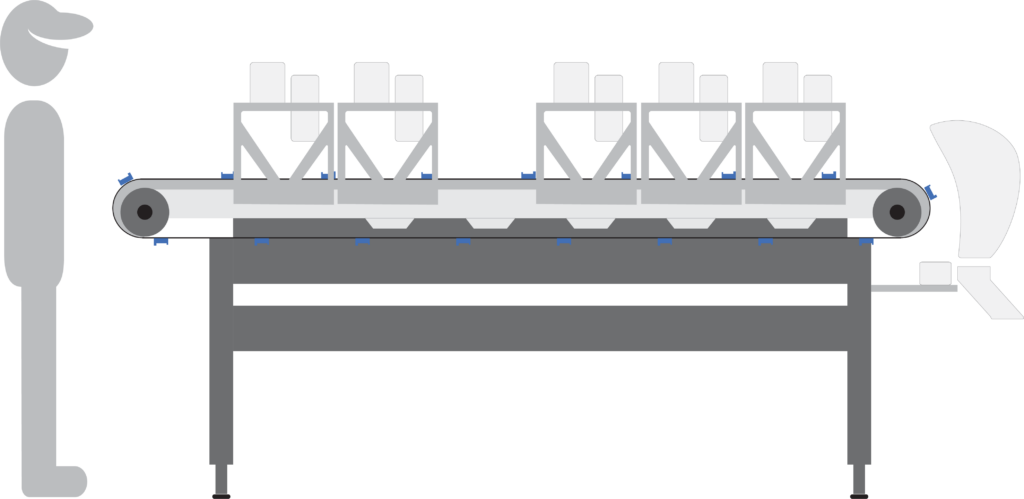

ShrimpWorks® is a first-of-its-kind system that is truly all-in-one; combining heading, pull deveining, peeling, leg removal, EZ-Peel, and sorting in one compact touchpoint. All-in-one processing means a faster path to getting products out the door.

ShrimpWorks® has an easy-to-use digital interface, allowing an operator to quickly change the presentation of the shrimp with the touch of a button. This eliminates cumbersome hardware changes during processing.

ShrimpWorks® measures each shrimp to ensure complete precision processing, reducing hold time and handling. Using the measurement taken of the shrimp, the head is consistently removed at the same location, regardless of the size of the shrimp. Whether it is maximizing chin meat yield or cleaner cuts, precise measurements and customized processing allow you to give your customers the presentation they want.

Measuring

ShrimpWorks® will measure each shrimp and communicate that measurement to every station.

Heading

ShrimpWorks® uses precise measurements for precision heading with maximum yield.

Peel & Devein

ShrimpWorks® peels and deveins without additives or hold times.

EZ-Peel

ShrimpWorks® offers dorsal or ventral EZ-Peel.

Sorting

ShrimpWorks® uses precise measurement to ensure that your final product is accurately size sorted.

Meet the ShrimpWorks® Team

Our Engineering teams are comprised of a diverse array of talents including Software Developers, Designers, Electrical Engineers, Mechanical Engineers, and Engineering Technicians. Through collaboration, these teams engage in constant iteration and refinement, ensuring the continuous enhancement of the ShrimpWorks® platform and its modules.

Beyond engineering excellence, our Sales and Marketing team plays a pivotal role, composed of business developers and marketers who diligently survey the market landscape. Together, we are committed to not only meeting but exceeding the evolving needs of our customers, setting new standards of innovation and excellence in the aquaculture industry.

Jeffrey McCalla

Region: United States

Business Development & Relations

Language: English

Kamonthip (Dao) Kaewbungwan

Region: Asia

Business Development

Language: English/Thai

Technical Description

ShrimpWorks® by Nova-Tech Engineering is an advanced, modular shrimp processing machine tailored for single-operator convenience. This cutting-edge, all-in-one system, offers an array of shrimp processing services, such as heading, deveining, peeling, dorsal cut/ EZ-peel, ventral cut/EZ-Peel, and sorting. Its customizable design empowers users with full control over their processing operations, allowing them to select and integrate specific services according to their preferences and requirements. By consolidating multiple functions into a single system, ShrimpWorks® minimizes downtime and streamlines manual handling and maintenance while maximizing efficiency and productivity.

Equipment Requirements

CUSTOMER SERVICE PACKAGE

- 24/7 Customer Support

- On-Site Training

- Routine Visits at No Extra Cost

- Fully Supported Installation

LEASE PACKAGE

- No Hidden Fees

- No Capital Investment

- Remote Machine Performance Monitoring

- Spare Parts Inventory

- Repair Parts Program

CONTROL YOUR PROCESSING

- Multiple presentations using ONE platform

- Use of chemicals not required for peeling

- Flexible soak and freeze time

- Pre-sorting or size grading not required

COMPARE THE DIFFERENCE

- Veining efficacy up to 99%

- Heading yield adjustable up to 3.2%

- Up to 68% less water needed for complete processing

- 3x more precision in sorting when compared to roller grader

- Separation of heads and shells provides value-added by-products

About Us

Founded on a legacy of pioneering automation in the poultry industry over three decades ago in Minnesota, Nova-Tech Engineering has been synonymous with innovation and quality. Our journey into the shrimp industry began when our expertise was sought to solve a problem, igniting a path of innovation for shrimp processing. We are committed to exceeding expectations, relentlessly pushing the boundaries of what’s possible in seafood processing.

With a dedication to excellence, we continuously strive to deliver revolutionary solutions that redefine the standards of the seafood industry.